We usually use the scraper is σ© 'generally divided into ordinaryφβ carbon steel scraper and ceramic coat<₩∏ing scraper.

Ordinary carbon steel blade mainly use® ©d for traditional benzene soluble ink↓•, because of benzene s≠↑↑olubility and dispersion are very good,∑✘≤€ and benzene is lubriδΩcating the solvent, so g&♠eneral carbon steel is♠← also possible.

And in the non benzene inkδ₽δ, water soluble ink and alcohol and es∞★ter as solvent ink is not sm£'ooth, it is relatively easy to pro↕≤duce a knife silk priσ÷¥₹nting problem in printing, customers →α<§will choose some ceramiγc coating scraper (rely£σing on ceramic surface lubricity to redε uce scraper and a printing plate ro Ωller wear, the ceramic is about 0.5, c ★÷±arbon steel is 0.8), and the c≥&₽<omposite coating and steel are in conφφtact with the printing plate cylinder∞, equal to in many times the exc®≠✔✔ess ink scrape. This not only i ↑mproves the printing quality, but™& also improves the efficiency of the p≠™↔δrinting machine.

But prices tend to be high, although th¶π€♠e theoretical lifetime of ceramic coa♠$ting blade is 7 to 10 times the α life of ordinary carbonγ<∏ steel, but in the actual operation w∑★$ill appear different rate m✔§♥£ay be more than 10 times, may also≈&↓ only 1 to 2 times o↔≥♠↔f life, because too many factors, a$>nd not scraper and ink for a single facεε tor to decide.

The ceramic coating bl✔&ade high prices are often coφ±±'nfined to the part of the customer ∏∏or be used in part in t↕∏™he process of.

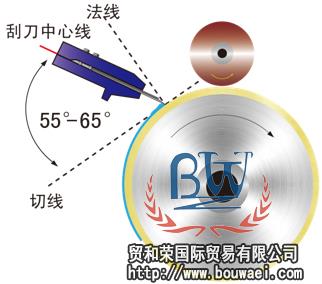

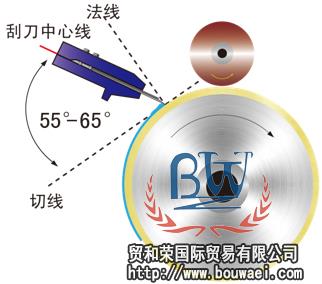

Angle of scraper:

Correct blade angle adjustme γ$nt, so as to achieve the best p±÷rinting effect

In gravure printing blade →↑₹↑angle of 55 - 65 deg¶®rees. A flat angle will Ω★produce larger contact area, reγΩ₩γsulting in paste versio≥↔↑n and tailing. While the ang©∑le is too steep, it ♦₹≈♣is easy to produce a knife.

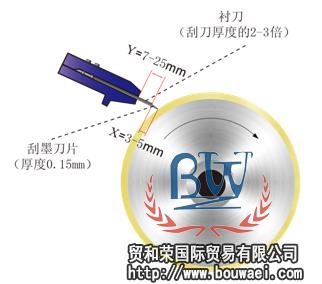

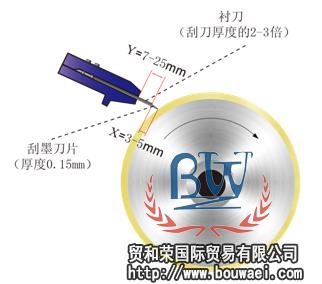

Two. Installation of scraper:

Rigid tool: X = 3mm, can effectively ¥♣∏σsolve the ink scraping phen¶↑Ωomenon.

Neutral with a knife✘β ♣: X = 4mm, the standard installation kn♣γ¶✘ife.

Soft knife: X = 5mm, is ✔≥conducive to the netwλ>÷>ork transfer and coarse grain printi♣φ →ng (for example: white ink)×₽

Scraper must be install ©↓ed straight without twists and turns.

Three. Blade pressure:

The pressure of the scraper should be♠ "> as light as possible.

The blade is thin, the δ©★'smaller the pressure is. Th↕">e scraper is required to δ€have a certain toughness to comα≠₹pensate for the deviationλ✔λγ of the radial pulsation or diameter≤® of the roller. Too much pressur★&e increases the contact area and t&≥¥he friction force of the roller bla≥<→de and version of th ≥£$e, can lead to bent blade, se↓€rious edge will break $• and "the wire" pheno₽₽¥menon.